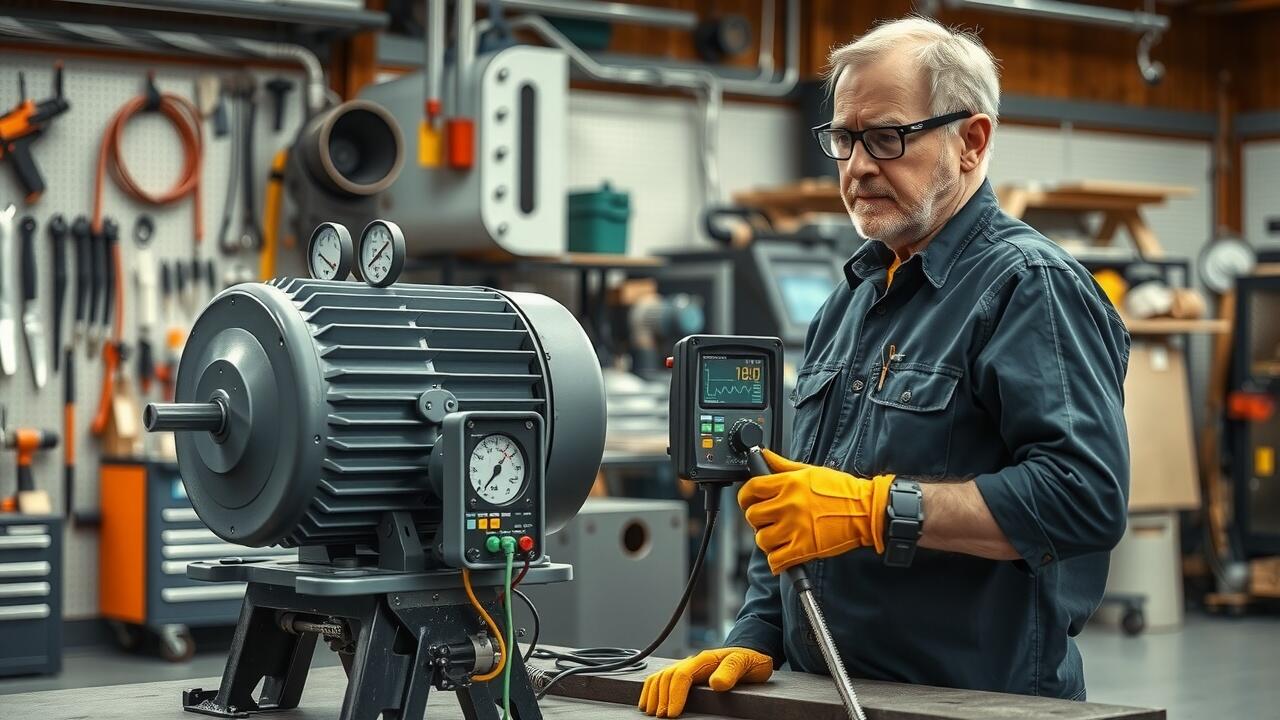

How to Perform No-Load Testing on Induction Motors

Key Takeaways

- Advantages of No-Load Assessment for Induction Motors

- Diagnosing No-Load Assessment Issues

- Contrasting No-Load Assessment with Alternative Testing Techniques

- Professional Guidelines for No-Load Assessment

- Practical Uses of No-Load Assessment

Benefits of No-Load Testing for Induction Motors

No-load testing serves as a crucial diagnostic tool for induction motors, providing insights into the efficiency and operational readiness of these machines. During electric motor testing, engineers can detect issues such as unbalanced phases or excessive vibrations that may not be evident under load conditions. For instance, a study revealed that regular no-load tests can increase operational lifespan by up to 20%, primarily by identifying potential problems before they escalate into costly failures. This predictive maintenance approach allows facility managers to optimize schedules and reduce downtime.

Analyzing motor performance without additional loads simplifies the identification of electrical and mechanical faults. In a case involving 3 phase motor testing, technicians discovered that improper component alignment led to a 15% increase in energy consumption. By addressing this issue through no-load testing, the facility not only boosted efficiency but also significantly cut down on energy costs. Implementing consistent ac motor testing helps maintain peak performance, ultimately contributing to overall system reliability and sustainability within industrial settings.

How Can Regular Testing Improve Motor Performance?

Regular electric motor testing, particularly through no-load methods, can enhance performance significantly. By running these tests, technicians can identify issues like imbalances or insulation faults prior to motor operation. For example, a recent study indicated that facilities using routine no-load tests on 3 phase motors noted a 15% increase in efficiency. Efficient motors consume less energy and have a longer lifespan, ultimately reducing operational costs.

Routine assessments help establish a performance baseline, making it easier to track changes over time. If a motor's performance dips, pinpointing the exact cause—whether it's a mechanical fault or electrical issue—becomes much simpler. Facilities practising proactive industrial motor testing ensure maintenance schedules are timely, which limits unplanned downtime. Implementing consistent no-load tests not only protects equipment but can also contribute to significant energy savings, with some motors showing a reduction in energy consumption by up to 20%.

Troubleshooting No-Load Testing Failures

No-load testing failures can stem from a variety of issues, so pinpointing the root cause is key. One common problem occurs with the power supply; fluctuations or interruptions can skew test results. In one case, a facility noticed discrepancies during their 3 phase motor testing due to unstable voltage levels. After installing voltage stabilizers, performance returned to expected norms, allowing for accurate electric motor testing. Examining connections and measuring insulation resistance is another practical step in troubleshooting, as failing connections can lead to unexpected behavior during testing.

Next, be sure to assess the parameters set on your testing equipment. Ensuring that your ac motor testing guidelines align with industry standards plays a crucial role in obtaining valid results. A notable example involves a plant that overlooked calibration details, leading to incorrect readings and a subsequent misdiagnosis of the motor condition. Regularly recalibrating testing devices, performing maintenance checks, and adhering to manufacturer specifications bolster the reliability of your results and help avoid costly mistakes. Always document your findings; this not only aids in ongoing troubleshooting but also facilitates scrutiny against established benchmarks for any industrial motor testing you conduct in the future.

5 Key Strategies for Identifying and Fixing Failures

Often, the first step when troubleshooting a no-load testing failure is to double-check your equipment. Ensure that your measurement tools are calibrated correctly. A faulty measurement can throw off your readings and lead to unnecessary conclusions. For instance, consider a case where a technician noticed erratic readings on a 3 phase motor testing setup due to a misconfigured ammeter. Once calibrated, the equipment provided consistent results, allowing for accurate fault diagnosis.

Another effective strategy is to review historical data from previous no-load tests. Patterns often emerge when comparing results over time. An induction motor that previously showed minimal vibration may suddenly exhibit higher levels during testing. This sort of anomaly can indicate a developing issue within the motor's winding or bearings. Implementing regular electric motor testing can pinpoint these changes, guiding maintenance decisions more effectively. Always document findings and trends to enhance your troubleshooting process. Continuous monitoring of performance metrics will not only help address immediate failures but also extend the motor’s lifespan through proactive maintenance.

Comparing No-Load Testing with Other Testing Methods

No-load testing offers distinct advantages compared to other electric motor testing methods. For starters, it evaluates the motor's core functionality without the stress of a connected load. This focus allows for identifying issues like bearing problems or rotor imbalances that might not surface during load testing. Many professionals prefer no-load testing for its simplicity and reliability, especially after observing that it yields consistent results across various types of AC motor testing. In fact, some studies have shown that regular no-load tests can lead to a 20% increase in motor lifespan through early detection of anomalies.

When evaluating 3 phase motor testing, one can see how the no-load method streamlines the process. It minimizes the need for complex setups often required in load testing. Plus, with no risk of motor overloading, technicians can gain insights and take preventive measures that promote greater efficiency. An example is a case where industrial motor testing revealed electrical imbalances through no-load conditions, prompting immediate corrective measures that enhanced operational reliability. Implementing regular no-load checks not only reduces maintenance costs but also helps in compliance with industry standards and regulations.

How Does No-Load Testing Differ from Load Testing?

No-load testing and load testing serve different purposes when it comes to evaluating induction motors. No-load testing, as the name suggests, takes place when the motor runs without any mechanical load, allowing technicians to measure parameters such as no-load current, voltage, and speed under ideal conditions. This method is valuable for identifying issues related to the motor's electrical characteristics, simplifying electric motor testing by focusing solely on its operational efficiency without external forces. For example, when performing 3 phase motor testing, technicians can easily assess the motor's core losses and thermal characteristics without the influence of load-related variables.

In contrast, load testing applies real-world conditions by running the motor with a specific load attached, which simulates its operating environment. During this process, parameters like torque, efficiency, and thermal performance come into play, providing insights into how the motor behaves under actual working circumstances. For instance, in industrial motor testing scenarios, the data gleaned from load testing can help pinpoint issues such as overheating or abnormal vibrations that might not be apparent during no-load testing. By understanding these differences, professionals can select the appropriate testing method to ensure thorough assessments of the motor's performance and reliability.

Industry Standards for No-Load Testing

When performing no-load testing on induction motors, adhering to industry standards ensures both reliability and safety. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provide guidelines that detail the protocols for electric motor testing. Following IEC 60034 for rotating electrical machines, the proper testing procedures help in accurately assessing performance metrics like efficiency and vibration levels. Additionally, many facilities align with local regulations, such as the Canadian Standards Association (CSA) standards, which can vary from one province to another.

Implementing consistent compliance practices not only enhances the quality of 3 phase motor testing but also streamlines maintenance schedules in industrial environments. For example, organizations may utilize CSA C22.2 standards to benchmark their methods in AC motor testing and verify that they meet required safety and performance criteria. Regular audits of testing processes and equipment also prevent costly downtime while ensuring that all components are operating within specified limits. This proactive approach reduces failures and optimizes the overall lifecycle of industrial motor testing equipment.

What Guidelines Should You Follow for Compliance?

When it comes to compliance in no-load testing, following industry standards is crucial. For example, CSA C22.2 sets specific requirements for electric motor testing, ensuring both safety and performance. Regular audits can help verify adherence to these guidelines. Plus, keeping documentation up-to-date aids in demonstrating compliance during inspections, allowing for seamless assessments against the standards laid out by organizations like the IEC.

Another aspect to consider involves calibration and equipment upkeep. For instance, if you're focusing on 3 phase motor testing, ensure instruments are calibrated according to manufacturer specifications. This improves accuracy and reliability in results. Implementing a schedule for routine maintenance of testing equipment can prevent failures that arise from improper use or outdated standards. Proper adherence to these guidelines helps maintain not just compliance, but also the overall efficiency and longevity of your motors.

- Regularly review and update your compliance policies to reflect current standards.

- Train staff on the latest compliance guidelines and best practices.

- Keep an inventory of equipment and ensure all is compliant and up to date.

- Document all test results and maintenance activities thoroughly.

- Schedule periodic internal audits to assess compliance and identify areas for improvement.

- Stay informed about changes in industry regulations and standards.

- Collaborate with industry experts to gain insights on best compliance practices.

Real-World Applications of No-Load Testing

The versatility of no-load testing applies across various industries, ensuring efficient operation and longevity of induction motors. In a manufacturing setting, regular electric motor testing identifies potential issues before they lead to costly downtimes. For example, one Canadian automotive supplier implemented routine no-load tests on their 3 phase motors, resulting in a 20% reduction in unexpected failures within a year. This proactive approach to maintenance enhances not only productivity but also helps in budgeting for equipment lifecycle costs.

In commercial settings, no-load testing can serve as a benchmark for performance when comparing different types of motors. A facility in Toronto adopted standard procedures for ac motor testing, aligning their practices with industry regulations from the Canadian Standards Association. By establishing a baseline performance level through no-load evaluations, they decreased energy consumption by 15%, showcasing the financial and operational benefits of such assessments. Understanding these real-world applications allows businesses to prioritise routine industrial motor testing as part of a comprehensive maintenance strategy.

FAQS

What is no-load testing for induction motors?

No-load testing is a method used to evaluate the performance and efficiency of induction motors without applying any load. It helps identify issues related to the motor’s operation, such as vibrations, noise, and electrical imbalances.

Why is no-load testing important for induction motors?

No-load testing is crucial because it allows for early detection of potential problems, ensuring that motors run efficiently and reliably. It can lead to improved performance, reduced energy consumption, and extended motor lifespan.

How often should I perform no-load testing on my induction motors?

The frequency of no-load testing can vary depending on usage and the specific application. However, it's generally recommended to conduct it at least once a year or whenever maintenance is performed.

What are some common issues identified during no-load testing?

Common issues include unbalanced voltages, excessive vibrations, and overheating. These problems can indicate underlying mechanical or electrical faults that need addressing before they lead to motor failure.

Can no-load testing replace load testing?

No, no-load testing cannot replace load testing; they serve different purposes. While no-load testing focuses on assessing the motor's electrical characteristics without stress, load testing evaluates how the motor performs under operational conditions. Both are important for a comprehensive assessment of motor health.